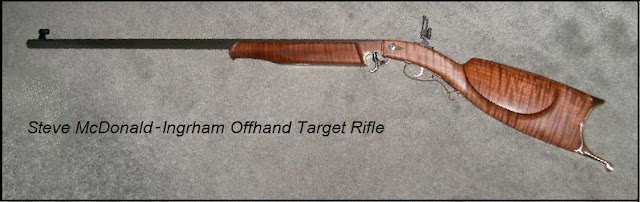

That seems to pretty much sum up the story of Steve McDonald, one of our readers who managed to get one of the Ingrham actions while they were available. Steve has always admired underhammer guns and wanted to build one of his own. He eventually got to that critical point where it was do or die for him, too. But lest I steal more of his thunder, I’ll get off the keyboard and let Steve tell his story.

Underhammer Dreams Do Come True.

By Steve McDonald

The underhammer desire didn’t hit me like a ton of bricks. It was a slow-growing obsession that started quite some time ago after seeing an old H & A for sale at a local gun show. At the time I couldn’t afford the asking price, but I made some mental notes on how simple the design was, and how well it fit me, and moved on.

I’ve always respected clever mechanical devices and I grew up in a “you shouldn’t own it, if you can’t fix it yourself” environment. My father was a very inventive machinist and proffered a credo that no mechanical challenge was ever too great. At least not too great to give it a try yourself before calling for backup. I made sure in my growing years that I learned how to use every tool he had in the house, and then some. Unfortunately, he did lack a certain eye for aesthetics. His end products always provided the desired results but usually at the expense of visual sense. I always assumed he studied under Rube Goldberg at some point in his career.

I, on the other hand, was always a fanatic for visual harmony. A connoisseur of beauty, and a crusader against even the slightest blemish on the surface of anything I ever constructed. It was always what was on the outside that counted, and less is more, as far as I was concerned. Kind of a visual OCD I guess. Maybe my potty training had something to do with it. But as nice as it sounds, I hardly had the skills to put my money where my compulsion was.

So I guess that might be why I was attracted to the under hammer in the first place. What a fabulously elegant device - sleek and to the point, yet fully functional. And, with plenty of room for tasteful adornment. Yep, the more I thought about it, the more I had to build one. And the journey began.

Over the years, my professional career seemed to keep me from my mechanical passions. Lack of workspace and very little extra time limited me to only dabble in small engine repairs or the occasional honey-do, to fix something around the house. But fortunately for me, my second passion of working with wood offered me at least a small outlet for my 3-dimensional talents. And when we were finally able to build a bigger home, I was incensed with putting a workshop in the basement. It was time to put my woodworking skills to work. So along with bird carving, furniture repairs and woodturning, I set my sights on making and repairing gun stocks. My basic plan now was to acquire an underhammer action and set out to making a beautiful stock for it.

I searched off and on, to find as much information on underhammers as I could. For about two years I gathered valuable tidbits and grew more excited about the possibility of building one. But finding a complete underhammer action ready made was proving to be difficult. But I kept looking.

My search led me to a man named Wade Ingram of Texas. A man I’ve never met in person but feel like I’ve known all my life. I saw Wade’s underhammer design on his website. Immediately I was intrigued. His design had all the features I was looking for. Clever and compact, but with an obvious strength that I was sure would stand the test of time. And the best part was the removable barrel feature. I had to have one. Unfortunately, Wade was no longer making his underhammer actions. He’d stopped making them some years before. But this wasn’t the end of the road. It seemed my inquiry to Wade opened up some valuable communication between us.

Wade and I corresponded by email for many months. I picked his brain about design and he was very pleasant in his replies about his actions. He sent me images of the various rifles he had made using his action and I of course, asked more questions. Somewhere along the way Wade became inspired to make a few more of his frames, and the emails continued.

Wade sent me pictures of the various processes involved with making one of his actions. He is an outstanding machinist and I felt like I was being let into the big boys club while he showed me his progress. I bounced ideas off him, and he asked for my feedback along the way. I’m sure I learned more than he from the experience but I could sense he was excited about the work.

Long story made short, the result of our months of correspondence ended up with me owning one of Wade’s underhammer actions. I couldn’t have been more proud to own anything else in my life. I recall the day his package arrived, I felt like a little kid on his birthday. The quality, craftsmanship and appeal of Wade’s action was astounding. But, best of all it was simple and elegant. I had a real job ahead of me to now make a stock that would measure up to the high standard of Wade’s action.

Steve's stockwork is a tasteful blend of racy and traditional lines and exhibits great skill in its making.

Steve chose a classic German schuetzen buttplate for his target rifle which

makes holding and controlling it much easier during a 20-shot offhand string of fire.

Next, I was off to see Andrew, another good friend a few towns away and an eccentric gunsmith who works exclusively on arms from the period of mid 1700s to the late 1800s. I wanted him to see this action for all its beauty, and to get his suggestions for how to begin this daunting task. He was the next important player in my quest as he guided me through several difficult moments in the stick making. However, he being used to working with field pieces carried by infantry and such, was insistent on making one strengthening modification to Wade’s design by adding a tang bolt boss on the lower tang to receive a hefty machine-thread tang screw for added strength. Normally in this design the upper and lower tangs are secured to the stock with separate wood screws. This mod, however, is definitely an improvement.

Seen here is the lower tang modification that Steve mentions in the story. The normal Ingrham action, as seen in Photo 1, does not use a tang bolt that secures both upper and lower tangs together. A tang bolt boss was added, as seen in Photo 2, which allows use of a full tang bolt to further secure the action in the stock and add stiffness to the finished rifle.

Making the escutcheons, as seen above, and setting the butt plate was a real challenge. The barrel I chose for the project was a .40 caliber Green Mountain barrel with aggressive rifling and quick twist. It was 36 inches long and it seemed all the way through the project that I would need to cut it down because it was cumbersome. But in the end, I left the length as it was. When the barrel locked up to Wade’s action, it was a marriage made in heaven.

A little special attention to final fit and finish and my underhammer was complete. I felt like I had made history. In fact I believe I did, because according to Wade this was the only action of his in this part of the country (New England). I completed this project about a week before my annual summer camping trip to the White Mountains. I would use this trip to inaugurate my underhammer and impress my camping buddies with my talent.

I chose a Lyman globe front sight and an unknown, but good quality, rear tang sight for this rifle. We test fired it and the performance was spectacular. The first three shots, made by three different people, made a two inch group on a steel plate at 25 yards. Later, at the shooting range, I did more test firing to help establish good loads. The results then were just as amazing with a group under two inches at 75 yards. I attribute a lot of the steadiness of this rifle to the smooth functioning of Wade’s action. It gives a crisp let off and strikes the cap with authority.

Recently I tested some pure lead cast pistol bullets with a diameter of .401. This suggestion came to me from my gunsmith friend. I lubed them on site with a little bore butter and fired 4 consecutive direct hits on a steel plate at 100 yards. I then moved over to the 200 yard steel plate and had 2 out three direct hits, without changing my sights from 100. Of course next I will put some paper down range to see how well it will group with a larger number of shots.

I really owe a debt of gratitude to Wade for helping me along with this project. And thanks also to the other handful of friends that played a role in my success. I now not only have a nice, unique handmade underhammer in my collection, but I have an amazing experience that I can share with anyone that will listen. “What next?” you may ask. Build another underhammer of course!

All photos copyrighted by Steve McDonald.

Thanks, Steve, for sharing your beautiful offhand rifle with us. Please keep us posted on your next project, too.

.

1 comment:

Excellent work. Dad was proud to be part of your project - David R. Ingrham

Post a Comment